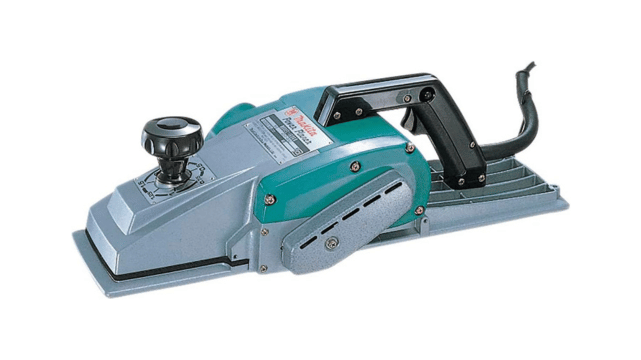

Shape and smooth your woodworking projects with precision using the best hand planer. This versatile tool is perfect for fine-tuning edges, leveling surfaces, and achieving a flawless finish on any type of wood. With a sharp, adjustable blade and ergonomic design, it offers excellent control and comfort, making it ideal for both professional woodworkers and DIY enthusiasts. Lightweight yet powerful, it easily tackles tough spots, ensuring smooth and even results every time. Elevate your craftsmanship with a hand planer built for accuracy, durability, and seamless performance.

Best Hand Planers Buying Guide

A hand planer is an essential tool for woodworkers, carpenters, and DIY enthusiasts who appreciate the precision and control offered by manual woodworking techniques. This versatile tool allows users to smooth, shape, and level wooden surfaces with remarkable accuracy, making it indispensable for tasks ranging from fine furniture making to basic home improvement projects. Whether you’re restoring antique furniture, fitting doors, or crafting custom woodwork, a quality hand planer can elevate the quality of your work and provide a level of satisfaction that power tools often can’t match. This comprehensive buying guide will walk you through the crucial factors to consider when selecting a hand planer, ensuring you make an informed decision that aligns with your woodworking needs, skill level, and project requirements.

Understanding Hand Planers

Hand planers, also known as bench planes or manual planers, come in various types and sizes, each designed for specific woodworking tasks. At their core, these tools consist of a sharp blade (iron) set in a body (stock) that allows the user to remove thin shavings of wood with each pass. The most common types include jack planes for rough work, smoothing planes for final finishing, and jointer planes for creating perfectly flat edges. Understanding the different types of hand planers and their intended uses will help you select the right tool or set of tools for your woodworking arsenal. Additionally, familiarizing yourself with the anatomy of a hand planer, including components like the frog, chip breaker, and adjustment mechanisms, will enable you to make more informed decisions about the features and quality of the tools you’re considering.

Key Factors to Consider

Planer Type and Size

The type and size of hand planer you choose should be based on the specific woodworking tasks you intend to perform. Jack planes, typically around 14 inches long, are versatile tools ideal for initial stock preparation and rough dimensioning. Their medium length allows for reasonably accurate flattening while being manageable for extended use. Smoothing planes, usually 9 to 10 inches in length, are designed for final surface preparation, capable of producing glass-smooth finishes on wood. Their shorter length allows them to follow slight contours in the wood surface. Jointer planes, which can be 22 inches or longer, are specialized tools for creating perfectly straight edges and flattening long boards. Their extended length acts as a reference, ensuring straightness over longer distances. For beginners or those with limited storage space, a well-tuned jack plane can serve as a good all-around tool. However, as your skills and project complexity grow, you may find the need for a set of planes that includes a jack, smoother, and possibly a jointer. Consider also specialty planes like block planes for end grain work or shoulder planes for cleaning up joinery. The size of the plane affects not only its intended use but also the user experience. Larger planes provide more reference surface and mass, which can aid in achieving flat surfaces but may be tiring to use for extended periods. Smaller planes offer more maneuverability and control for detail work but require more skill to achieve large flat surfaces.

Blade Material and Quality

The quality of the blade, or iron, is paramount in determining the performance and ease of use of a hand planer. High-carbon steel blades are traditional and can achieve a very sharp edge, but they may require more frequent sharpening. High-speed steel (HSS) blades offer improved edge retention, staying sharp longer under heavy use. For the ultimate in edge retention and sharpness, some premium planes feature blades made with powdered metal technology or laminated with high-hardness alloys like A2 or PMV-11 steel. These advanced materials can hold an edge significantly longer than traditional steels, reducing the frequency of sharpening sessions. However, they may also be more challenging to sharpen when the time comes. Consider your willingness to sharpen frequently versus the desire for extended periods between sharpenings when choosing blade material. The thickness of the blade is another important factor. Thicker blades tend to produce less chatter (vibration during cutting), resulting in smoother cuts, especially in figured or difficult woods. Some high-end planes feature additional rigidity through improved blade bedding or thicker chip breakers. Pay attention to the quality of the chip breaker as well, as it plays a crucial role in preventing tear-out by breaking the wood fibers ahead of the cutting edge. A well-designed chip breaker should mate perfectly with the back of the blade to prevent shavings from becoming lodged between them.

Body Construction and Materials

The body, or stock, of a hand planer plays a crucial role in its performance, durability, and overall user experience. Traditionally, planes were made entirely of wood, and some craftsmen still prefer wooden planes for their light weight and the way they glide smoothly over wood surfaces. However, most modern hand planers feature metal bodies, typically made of cast iron or ductile iron. These materials provide excellent stability, vibration dampening, and wear resistance. Cast iron planes are prized for their mass, which helps to power through cuts and maintain momentum during long planing sessions. Some premium planes feature bodies made from materials like bronze or brass, which offer corrosion resistance and aesthetic appeal, though they come at a higher price point. The sole of the plane, which is the bottom surface that contacts the wood, should be perfectly flat to ensure accurate cuts. High-quality planes often undergo extensive machining and lapping processes to achieve this flatness. Consider the finish of the sole as well; a smooth, polished sole will glide more easily over the wood surface, reducing friction and user fatigue. Some planes feature soles with slight hollows or relief areas to reduce friction further, though this is a matter of personal preference and can affect the plane’s versatility. The overall build quality of the plane body, including the precision of cast or machined parts and the smoothness of adjustments, contributes significantly to the tool’s performance and longevity.

Adjustment Mechanisms

The ease and precision of blade adjustment can greatly impact your efficiency and the quality of your work with a hand planer. Look for planes with smooth, precise adjustment mechanisms for both blade depth and lateral alignment. Many modern planes feature a screw adjustment for blade depth, allowing for fine-tuning of the cut thickness. This system should operate smoothly without backlash, allowing you to make predictable, repeatable adjustments. Lateral adjustment, which allows you to align the blade parallel to the sole, is crucial for achieving even cuts across the width of the board. Some planes feature a simple lever for this adjustment, while others may have more sophisticated systems that offer finer control. Consider planes with adjustment mechanisms that can be operated while wearing gloves or with slightly dirty hands, as this is often the case in a workshop environment. The presence of a lever cap that can be easily engaged and disengaged for blade removal and replacement is also a valuable feature, especially when you need to sharpen or change blades frequently. Some premium planes offer additional refinements like adjustable mouths, which allow you to open or close the gap in front of the blade to control tear-out in different wood types. While these advanced features can enhance the versatility and performance of the plane, they may also add complexity and cost. Evaluate your needs and skill level to determine whether such features are necessary for your woodworking tasks.

Ergonomics and Comfort

Given that hand planing can be a physically demanding task, especially for larger projects, the ergonomics and comfort of the tool are crucial considerations. The shape and size of the plane’s handles or totes (rear handles) and knobs (front handles) significantly affect how comfortably and effectively you can use the tool. Look for planes with handles that fit your hand size and grip style comfortably. Some planes offer adjustable or interchangeable handles to accommodate different hand sizes or preferences. The angle and position of the handles should allow for a natural wrist position during use, reducing fatigue during extended planing sessions. The overall weight and balance of the plane are also important ergonomic factors. While a heavier plane can provide more momentum for powering through cuts, it may also lead to faster fatigue. Conversely, a lighter plane might be easier to maneuver but may require more effort to maintain consistent pressure. The ideal weight often depends on the specific tasks you’ll be performing and your physical capabilities. Consider also the texture and material of the handles; some users prefer the warmth and feel of wooden handles, while others may opt for modern materials like polymer or rubberized coatings for enhanced grip, especially in humid conditions. The shape of the plane’s sides can also affect comfort and control, particularly when using the plane for shooting (planing end grain on a shooting board). Planes with smooth, perpendicular sides provide a stable reference surface for this task.

Additional Features and Accessories

Many hand planers come with additional features or accessories that can enhance their functionality and versatility. One valuable feature to consider is an adjustable mouth, which allows you to vary the size of the opening in front of the blade. A tighter mouth helps to reduce tear-out when working with figured or difficult grain, while a more open mouth allows for thicker shavings in rough work. Some planes come with multiple base plates or soles that can be interchanged to suit different tasks, such as a straight sole for general work and a cambered sole for smoothing. Depth stops can be useful for maintaining consistent thickness when removing a specific amount of material. Consider planes that come with or are compatible with accessories like fences for edge jointing or chamfering, or depth gauges for precise stock removal. The availability of replacement parts and accessories can also be an important factor, especially for high-end or specialty planes. Some manufacturers offer extensive customization options, allowing you to tailor the plane to your specific needs over time. Additionally, consider the storage and protection options available for the plane. Some come with fitted cases or covers to protect the tool when not in use, which can be particularly valuable for preventing damage to the precisely machined surfaces of premium planes.

Conclusion

Selecting the ideal hand planer involves carefully considering factors such as the type and size of the plane, blade quality, body construction, adjustment mechanisms, ergonomics, and additional features. By thoroughly evaluating these aspects and aligning them with your woodworking needs, skill level, and project requirements, you can invest in a hand planer that will serve as a reliable and satisfying tool for years to come. Remember that the best hand planer for you is one that balances performance, comfort, and versatility while meeting the unique demands of your woodworking style and projects. Take the time to research different models, read user reviews, and if possible, try out various planes to get a feel for their handling and performance. With the right hand planer in your toolkit, you’ll be well-equipped to tackle a wide range of woodworking tasks with precision and craftsmanship, enjoying the tactile satisfaction and connection to traditional woodworking methods that these timeless tools provide.