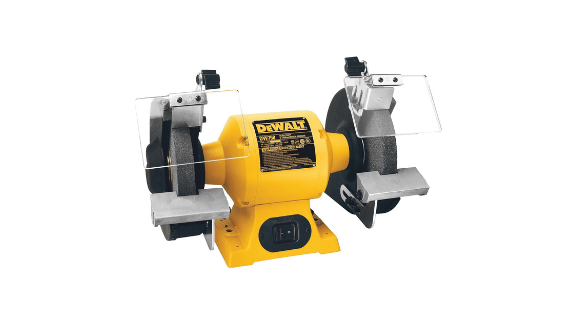

Master your sharpening, grinding, and polishing tasks with the best bench grinders, designed to deliver precision and power. Built for durability, these versatile tools handle everything from sharpening blades to shaping metal with ease. Perfect for both professional workshops and home garages, they offer a stable platform for accurate, repeatable results. With powerful motors and adjustable features, you can tackle a wide range of tasks efficiently. Enhance your tool collection with a top-rated bench grinder, and experience superior performance for all your grinding and sharpening needs.

Best Bench Grinder Buying Guide

Designed to perform a variety of tasks, including sharpening tools, smoothing metal surfaces, and shaping various materials. With its rotating abrasive wheels, a bench grinder can quickly remove material, deburr edges, and restore worn tools to their optimal condition. Selecting the right bench grinder for your needs is crucial to ensure efficient and safe operation. This comprehensive buying guide will walk you through the essential factors to consider when purchasing a bench grinder, helping you make an informed decision that will enhance your workshop capabilities and streamline your projects.

Understanding Bench Grinders

At its core, a bench grinder consists of a motor that drives two abrasive wheels mounted on opposite ends of a shaft. These wheels rotate at high speeds, typically between 3,000 and 3,600 RPM, allowing for rapid material removal and shaping. Bench grinders are commonly used for sharpening chisels, drill bits, and other cutting tools, as well as for grinding down welds, removing rust, and polishing metal surfaces. The versatility of a bench grinder makes it an essential tool for metalworkers, woodworkers, and general maintenance professionals. Understanding the key components and features of bench grinders will help you select a model that best suits your specific needs and working environment.

Key Factors to Consider

Motor Power and Speed

The heart of any bench grinder is its motor, and the power output directly affects the tool’s performance and capabilities. Motor power is typically measured in horsepower (HP) or amperage (amps). For light to medium-duty tasks, a motor ranging from 1/3 HP to 1/2 HP (or about 2.5 to 4 amps) is usually sufficient. However, for more demanding professional use or frequent heavy-duty grinding, consider models with motors of 3/4 HP to 1 HP (or 5 to 8 amps). These more powerful motors can handle tougher materials and maintain consistent speed under load, reducing the risk of bogging down during operation. Additionally, some advanced bench grinders offer variable speed settings, allowing you to adjust the RPM for different materials and tasks. This feature can be particularly useful when working with heat-sensitive materials or when performing precision grinding operations that require lower speeds to prevent overheating.

Wheel Size and Type

The size of the grinding wheels is a crucial factor that determines the grinder’s capacity and versatility. Common wheel sizes for bench grinders range from 6 inches to 8 inches in diameter, with some heavy-duty models offering 10-inch or even 12-inch wheels. Larger wheels provide more surface area for grinding, which can be beneficial for working on larger pieces or for faster material removal. However, they also require more powerful motors to maintain effective speeds. Consider the types of projects you typically work on and the size of the tools or materials you’ll be grinding when selecting wheel size. It’s also important to consider the types of wheels that come with the grinder and their intended uses. Most bench grinders come with a coarse wheel for heavy material removal and a finer wheel for precision work or tool sharpening. Look for grinders that offer easy wheel changing mechanisms and compatibility with a wide range of wheel types, including wire brush wheels, polishing wheels, and specialized abrasives for different materials.

Build Quality and Durability

The construction and overall build quality of a bench grinder significantly impact its performance, longevity, and safety. Look for models with robust cast iron or steel bases that provide stability and minimize vibration during operation. The motor housing and wheel guards should be made of durable materials that can withstand the rigors of workshop use and protect against flying debris. Pay attention to the quality of the bearings and shaft, as these components are crucial for smooth operation and long-term reliability. Some high-end models feature precision-machined components and balanced wheels that further reduce vibration and improve accuracy. Consider the overall weight of the grinder as well; while heavier models can be more stable, they may be less convenient if you need to move the tool frequently. Lastly, check for features like dust-sealed switches and protected motor windings that can extend the life of the grinder in dusty workshop environments.

Safety Features

Safety should be a top priority when selecting a bench grinder. Look for models that come equipped with comprehensive safety features to protect you during operation. Essential safety elements include sturdy wheel guards that enclose a significant portion of the grinding wheels to contain debris in case of wheel breakage. Adjustable eye shields or spark deflectors are crucial for protecting your face and eyes from flying particles and sparks. Some advanced models offer tool rests with positive stops at common angles, making it easier to maintain consistent grinding angles and reducing the risk of accidents due to tool slippage. Consider grinders with quick-stop or brake systems that rapidly halt wheel rotation when the power is turned off, minimizing the risk of injury during wheel changes or when stepping away from the machine. Additionally, look for models with rubber feet or mounting holes that allow you to securely anchor the grinder to your workbench, enhancing stability during use.

Adjustability and Precision

The ability to make precise adjustments can significantly enhance the versatility and effectiveness of your bench grinder. Look for models with easily adjustable tool rests that can be set at various angles to accommodate different grinding tasks. Some high-end grinders offer tool rests with precise angle markings or even digital angle gauges for ultra-accurate setups. The distance between the tool rest and the wheel should be easily adjustable to compensate for wheel wear over time and to accommodate different tool sizes. Consider models with fine-grit dressing tools or built-in wheel dressers that allow you to true and clean the wheels, maintaining their shape and cutting effectiveness. For those who frequently work on precision tasks, look for grinders with features like work lights or magnifying lenses that can improve visibility and accuracy during fine detail work.

Noise and Vibration

Bench grinders, by nature of their high-speed operation, can produce significant noise and vibration. However, well-designed models incorporate features to minimize these issues, making for a more comfortable and controlled working environment. Look for grinders with balanced wheels and precision-machined components that reduce vibration at the source. Some models feature rubber or anti-vibration mounts that help isolate the motor and wheels from the base, further reducing transmitted vibration. In terms of noise reduction, consider models with enclosed motor housings or those that use quieter induction motors. While these features may increase the initial cost of the grinder, they can significantly improve the user experience, reduce operator fatigue, and potentially extend the life of the tool by minimizing stress on components.

Additional Features and Accessories

Many bench grinders come with additional features and accessories that can enhance their functionality and convenience. Built-in work lights can greatly improve visibility, especially when working on small or intricate pieces. Some models offer integrated cooling trays that allow you to quench tools during sharpening, preventing overheating and maintaining the temper of the metal. Look for grinders that come with a variety of wheels or those that offer easy compatibility with a wide range of aftermarket wheels and accessories. Storage compartments for tools and accessories can be a handy feature, keeping your workspace organized. For those who value versatility, some advanced bench grinders offer attachments for tasks like belt sanding or buffing, expanding the tool’s capabilities beyond standard grinding operations.

Conclusion

Selecting the ideal bench grinder involves carefully considering factors such as motor power, wheel size and type, build quality, safety features, adjustability, and additional functionalities. By thoroughly evaluating these aspects and aligning them with your specific needs, workspace constraints, and typical projects, you can invest in a bench grinder that will serve as a reliable and versatile tool in your workshop for years to come. Remember that the best bench grinder for you is one that balances performance, safety, and value while meeting the unique demands of your work. Take the time to research different models, read user reviews, and if possible, test the equipment before making your final decision. With the right bench grinder at your disposal, you’ll be able to tackle a wide range of sharpening, grinding, and shaping tasks with improved efficiency and precision, elevating the quality of your metalworking, woodworking, or general maintenance projects to professional standards.